ROTATING EQUIPMENT

SEIM S.R.L SCREW PUMP

SEIM SRL has been operating in the market for over 40 years and has reached a position of leadership, having installed over two million screw pumps, over 50,000 heat exchangers and the same number of safety valves, for numerous industrial sectors, such as Energy, Petrochemical, Oil and Gas, the Paper and Metal industry.

RECIPROCATING COMPRESSOR

Compressor Company has designed, manufactured, and serviced its brand of positive displacement, piston type, reciprocating gas compressors API618. Having made many significant contributions to the advancement of compressor technology, including its patent for the world’s first multi-stage compressor in July 1881, Norwalk continues its commitment to engineering innovation and design of first-rate products, offering approximately 100 quality products.

STROBL PUMPEN GERMANY CENTRIFUGAL PUMP

Strobl Pumpen GMBH & Co. KG offer a wide range of pumps for different applications and also complete systems, optimized to customer needs. This strategy also helps Strobl Pumpen customers to realize the projects in an inexpensive way and handling conservative with resources. The API610-OH1, OH2, OH3, OH4, OH5, BB4 of pump range as vertical/horizontal process pump, multistage pump, compact pump, submersible pump and sump pump.

Controlled Volume Pump

- Manufactured according to API 675 Std., “non lost-motion” type construction,

- continuous adjustment of capacity, from 0 to 100% while the pump is at rest or running,

- metering accuracy better than 1% over the normal operating range from 10 to 100% of capacity,

- patented capacity adjustment system, with mechanical plunger return stroke,

- completely enclosed crankcase made of cast iron,

- also available (limitated range) in accordance with API 674 Standards with special execution for plunger thrust higher than 30.000 N.

Chemical Injection Packages

In answer to growing demands from the main engineering companies, we are extended its activities to cover the design of integrated dosing systems including pumps. The market increased progressively allowing us to become one of the more consolidated supplier inside the Malaysia major lists.

Special Execution Pump

- Special execution pump for high temperature molten sulphur (150 °C) with integral jackets, cooling device for plunger, safe coupling between pump and motor including torque limiter, developed into an extended range of capacity,

- special execution pump for beverage industry, usually developed by two pumps with indipendent stroke adjustment, the rst with high capacity for water (double e ect pump), the second with lower capacity for syrup (traditional simple e ect pump), all wetted materials FDA certi ed, one only common electric motor, and power transmission,

- special execution pump for high pressure services (more than 300 barG) powered by diesel engine.

Hollow Disc Pumps

- Low operating speed as best guarantee for long service life,

- adaptable for any kind of liquid, from the most uid to the most viscous,

- self priming operating conditions, NPSH required less than 3 meters, no foot valve is needed,

- reversible ow by operating the pump in the opposite direction,

- all mechanical seals as per API Standards could be installed to meet any process requirement.

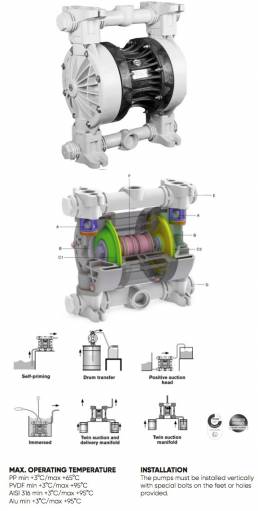

AIR OPERATED DOUBLE DIAPHRAGM PUMP (AODD)

Air operated diaphragm pumps are characterized by exceptional performance, power and strength, making them ideal for pumping liquids with high apparent viscosity even if containing suspended solids.

The stall-prevention pneumatic system assures a safe pump running and it does not need lubricated air.

Self-priming dry capacity even with considerable suction head, fine tuning of speed without pressure loss and the possibility of dry operation without suffering damage mean that these pumps offer unrivalled versatility. In addition, the huge choice of construction materials allows selection of optimum chemical compatibility with the fluid and/or environment without neglecting the temperature range. They are specifically designed for demanding applications with high humidity or in potentially explosive atmospheres (ATEX certification).

- Available in PP, PVDF/ECTFE, ALUMINIUM and AISI 316 STAINLESS STEEL

- Use in potentially-explosive atmospheres (ATEX zone 1 - 2 certi cation)

- Suitable for demanding applications and high-humidity environments

- Dry operation

- Dry self-priming

- Actuated using non-lubricated air

- Stall-prevention pneumatic circuit

- Adjustable ow rate and head

- Fine tuning of motor speed at constant pressure

- Twin-manifold option (two suction and two delivery)

- Bench or ceiling installation

- Three suction and delivery positions

- User-friendly maintenance and parts replacement

- Excellent performance and value for money

MIXERS / AGITATORS

Rotating mixers include gear driven top, bottom, and side entering con gurations for all your agitation applications. A wide selection of impellers and auxiliary equipment such as seals and lubrication systems are speci cally designed to optimize the mixing solution. Also available is a range of small mixers in both direct drive and gear reduced units for standard smaller scale applications.

In the business world, everyone is paid two coins: cash and experience. Take the experience first; the cash will come later.

Harold S. Geneen (1910 — 1997)